It is composed of Congxin Semiconductor- Shanghai Biken New Material Technology Co.,Ltd., which is responsible for the R&D, production, sales and modular management of software application of RFID radio frequency technology.

Company Intruduction

- Core advantages :

providing complete solutions for RFID applications in the tire industry : from RFID core chips, to inlay, to packages, to adhesive for electronics industry packaging, to printing , to fixed readers, to handheld readers, to application software. The design and production capacity for RFID in special applications ranks among the top in the country, leading in the industry - R&D Capability :

Special adhesives ( including : composite materials adhesive, conductive adhesive, thermosetting adhesive ) electronic industry ( including : chip , design antenna design ) design and production of special RFID tags, production automation system design and integration, pattern recognition system underlying software. - Qualifications :

International: GS1 Global, EPC Globa, AIM Global, Rain RFID, ISO 9001;

| RFID : | 1. One to many |

| 2. Non – Line – of – Sight | |

| 3. Read & Write | |

| 4. Difficult to copy |

| Barcode : | 1. One to one |

| 2. Line – of – Sight | |

| 3. Read Only | |

| 4. Easy to copy |

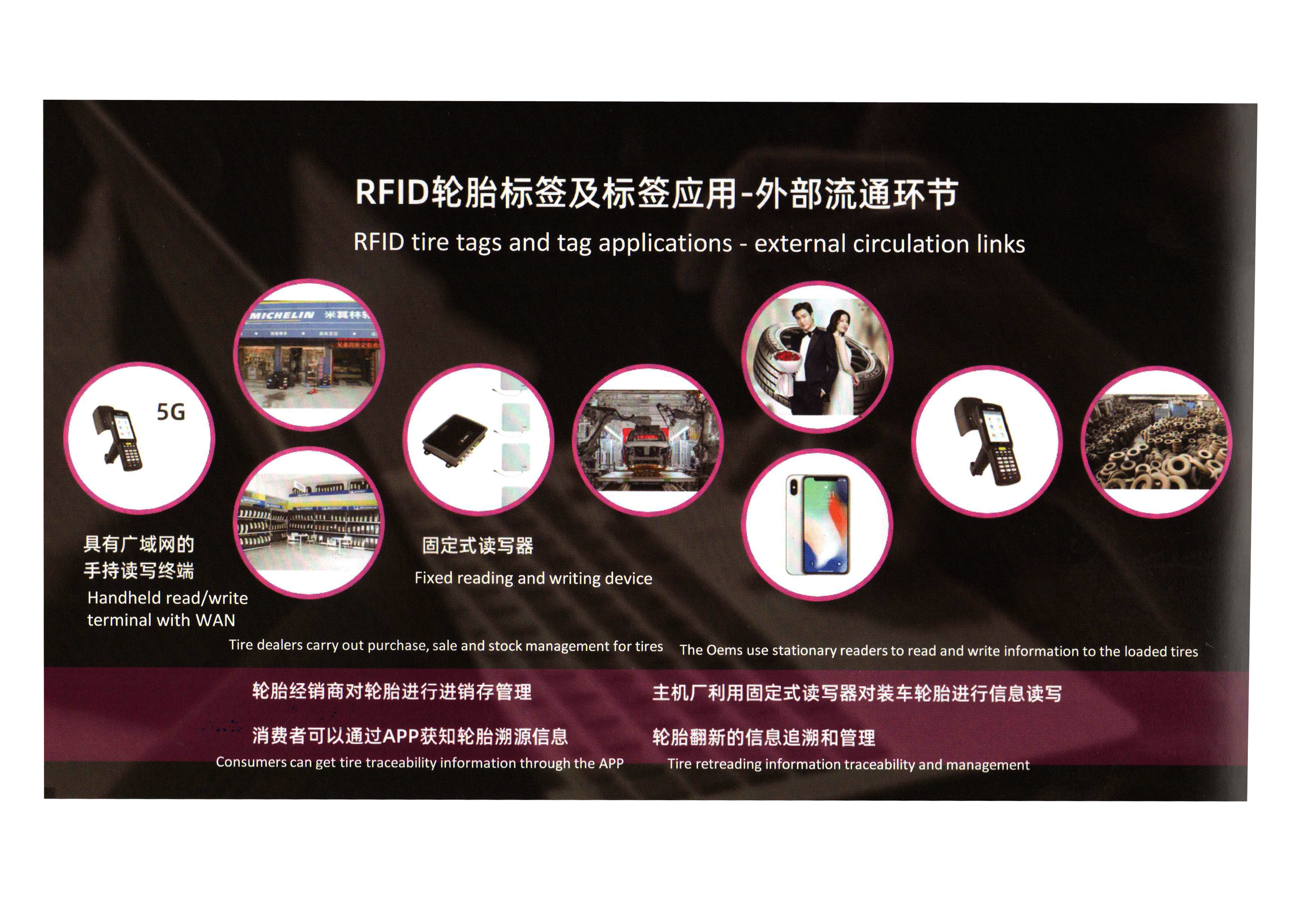

RFID Tire tags and tag applications – External Circulation links >> RFID Tire tags and tag applications – Internal processes

Application in the production Process >> Application in the warehousing process

FC – TRL – 001 Technical Specification

| Product Type | UHF ultra high frequency RFID electronic tag |

| Communication Protocol | ISO 18000-6C |

| Operating Frequency | Global 865-928 MHz |

| Chip | InpinjR6P (can be adjusted according to customer requirements) |

| Memory Configuration | 128bits ( 16- bit number ) |

| EPC memory contents | Label default writes unique code |

| Read/Write Distance | After embedding, read and write distance can reach 3 meters post tire vulcanization |

| Substrate | Vulcanizable resin |

| Weight | 0.6g/pc |

| Size | 75x8x1.2mm ( suitable for all-steel tires) |

| Operating temperature | -50°C to + 85°C |

| Maximum Thermal Resistance Temperature | Long-term tolerance temperature is not greater than +230°C, short – term tolerance +280°C |

| Voltage resistance performance | The reliability of the finished tire under 450KPa tire pressure was verified |

| Chemical resistance | Various acid and base solvents |

| Service life | Ten years |

| Read times | It can be rewritten 100,000 times |

| Environmental factor | The temperature is +20°C and the relative humadity is 50% for 1 year |

FC – TRL – 002 Technical Specification

| Model | FC – TRL – 002 |

| Operating Frequency | 920-925 MHz |

| Chip | AlienH4 ( chip can be adjusted according to customer requirements ) |

| Memory | EPC: 128bits;User:512bits |

| International standard | ISO18000-6C |

| Laminated Size | 36mm x 9mm x 0.45 mm |

| Weight | 0.3g |

| Operating temperature | -40°C ~230° |

| Storage temperature | -65°C ~180° |

| Volatage resistance performance | Reliability verification of finished tires under 450KPa pressure |

| Data retention | 10 years |

| Data writing performance | Can be rewritten 100,000 times |

| Reading Distance | 3 meters |

| Applicable surfaces | Inside rubber |

| Installation method | Patch application |

RFID tire tags and tag applications – application value – production and R&D stages

Application in the production process :

- By scanning the tire labels, information collection and recording of semi – finished tire

products in various processes is achieved, supporting batch reading function, allowing for large amounts of tire label information to be collected at once, and data is uploade to the management system in real- tima through the network , realizing intelligent information collection and management of all production links of tires, significantly improving work efficiency and reducing enterprise costs;

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.